![]()

Environmental impact

Meet your sustainability targets

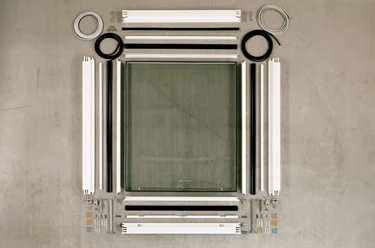

Working to reduce our impact on the environment is an important part of our philosophy, and this is reflected in the choice of materials, suppliers and manufacturing processes that are employed to make our windows and doors. We can provide the advice and guidance required to meet project-specific sustainability targets.